Tuning Rules for PI and PID

Determining Which Controller to Use

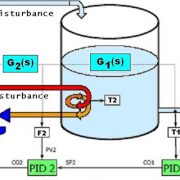

A key challenge in setting up a control system is determining what type of controller to use. The PID controller is generally accepted as the standard for process control, but the PI controller is sometimes a suitable alternative. A PI controller is the equivalent of a PID controller with its D (derivative) term set to zero.

It is important to understand how controllers interact with each different type of process. For details, see Table 1.

Table 1 – How PI and PID Controllers Interact with Different Kinds of Processes

| Controller |

Pl Controller |

PID Controller |

| Effective for These Processes |

Fast processes, such as flow, pressure, and some temperature loops. |

Slower processes, such as level and insulated temperature. |

| Tuning Parameters |

P = Proportional

I= IntegralPl controller is the equivalent of a PID controller with its D (derivative) term set to zero. |

P = Proportional

I= Integral

D = DerivativeThe derivative term is particularly important for integrating processes, such as level, position, & well-insulated temperature.In general, using a derivative term can significantly increase the speed of the response of a non-integrating process and suppresses overshoot. |

| Response Speed |

Response is slower, thus enabling a smooth and accurate PV change. |

Response is faster, thus enabling setpoint to be reached more quickly. |

| Overshoot |

Overshoot will likely occur. |

Reduced or no overshoot. |